Heatlift HW

Hot Water Heat Pump

Decarbonizing industrial and district hot water production

Heatlift HW is a high-temperature heat pump specially engineered for district heating and industrial applications aiming at decarbonizing the hot water production.

Healitft HW upcycles waste heat from the industrial processes using it, such as cooling loops, humid air and flue gas condensation, direct process cooling, or any other ambient and industrial resource that typically dissipate into the environment.

By capturing this low-grade heat, Heatlift HW elevates its temperature to generate hot water and superheated water up to 210°C used for the industrial processes or district heating networks.

Industrial heat pumps are the most practical and efficient technology for replacing natural gas and fossil fuel boilers and burners with locally produced renewable energy, supporting industries in their transition towards greener and more efficient operations.

Key technical features

Low-grade waste heat source

Hot Water Heat Pump

Superheated water

Extensive heat source compatibility

Extensive heat source compatibility

Compatible with a variety of waste heat sources:

-

Cooling loops and industrial refrigeration

-

Humid air and flue gas condensation

-

Direct process cooling and condensation

-

Freshwater and district cooling loops

Energy efficiency optimisation

Energy efficiency optimisation

-

Direct hot water production without fossil fuel combustion

-

Optimized COP and temperature lift

-

Reduced OPEX and low maintenance requirements

Hot Water Production

Hot Water Production

-

Hot water temperature : Up to 210°C

-

Water inlet temperature : Up to 140°C

Heatlift HW is using standard components and architecture designed for very high temperatures using various waste heat resources while offering maximized Coefficient of Performance (COP), temperature lift, reliability and low maintenance requirement.

Heatlift HW integration

Heatlift HW is engineered for full integration into existing industrial and district heating networks, including :

-

Low-grade waste heat recovery systems to maximise efficiency

-

Complementary or peak heating systems when required to meet process demands

-

Collaboration with major EPC contractors specialising in waste heat recovery, district heating and industrial site integration

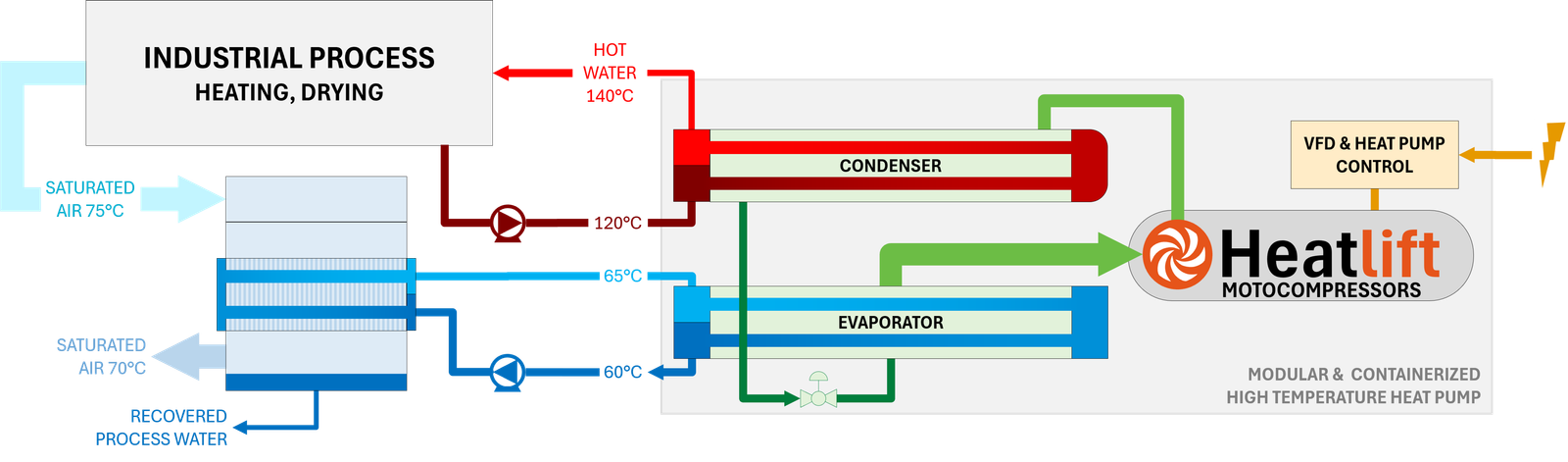

Example of Heatlift HW integrated into a complete Heat Pump system for an industrial process

Why using Heatlift HW

Replacing fossil fuel boilers

By producing steam using the unused heat from the process, Hetalift HW provides an innovative alternative to replace fossil fuel boilers and contribute to the decarbonization of the industry.

Saving operational costs

Since steam is generated using the unused heat from the process, the final energy consumption is significantly reduced, resulting in substantial cost savings in water production.

Delivery high-grade hot water

Heatlift HW produces high-quality industrial superheatder water thanks to its optimised system, with a maximised COP, high reliability and low maintenance requirements.

Tailored solutions for customers

Discover all our products

At Heatlift, we offer both standard and custom heat pump systems integrated into our clients’ processes to efficiently generate steam, hot water, hot air, or directly heat processes by upcycling waste heat generated within the same process.

HTHP for Steam Generation

HTHP for Hot Air production

HTHP for Hot Water production

Let’s discuss your project

To learn more about how our solutions can meet your industrial heating needs, please contact us directly.